Should Plywood Be Rolled Or Spray Painted

When edifice, y'all may put a lot of thought into the floor coverings, but what nearly the sub-flooring construction? Both are important to ensure a sustainable issue. Lance Turner surveys the options.

This article was kickoff published in Issue 143 (Apr-Jun 2018) of Renew mag.

When building a home, often very little thought is given to the type of floor and sub-floor construction used. Yet different sites need different materials, with some being far more appropriate for particular sites. The design of the rest of the house volition too help make up one's mind the type of floor and sub-flooring used.

Your architect will have proficient ideas about the best floor organisation to use, based on their feel with the type of edifice system you are using and the site specifics. But it helps to take a expert agreement of the flooring systems bachelor, so that you can consider the pros and cons of dissimilar systems and materials, and ensure that your sustainability or other requirements are met.

So let's have a wait at the most mutual types of floor systems (or, more accurately, sub-flooring systems), the materials nigh unremarkably used and the types of flooring materials they can support.

Flooring requirements

A floor/sub-floor system must obviously be able to bear the unabridged load on superlative of it, potentially including the house, contents and occupants (some floor structures, such equally upper floors, will but demand to support the contents/occupants).

The floor'southward basis arrangement must be suitable for the type of soil you have on your block. A soil report will be required which will tell you your soil blazon and how reactive information technology is. Reactive soils are soils with a high clay content which swell when moisture and compress every bit they dry. This expansion and contraction can cause structural bully, sinking and other site issues. Meet www.chip.ly/2oKu9GC for a quick rundown of soil types.

The level of insulation required for your dwelling volition likewise be a factor in the type of floor you select. If you lot are in a cold climate then y'all will demand a highly insulated flooring, so an insulated slab or a floor on stumps that tin can exist insulated underneath will exist required.

Insulation doesn't just mean thermal; you should also consider noise. For detached dwellings, dissonance transfer up through a ground slab is normally non an issue. Downwardly racket transfer from an upper level through a suspended slab to the lower level can be a problem, and underslab insulation can reduce this. The same applies to a floor on stumps—underfloor insulation will reduce noise ingress, especially if the insulation is acoustic form.

Of course, durability is also important: the floor must last the life of the home—for case, you don't want to accept to be restumping in 10 years due to degradation of the stumps or soil motion.

Thermal mass must also be considered if your house design makes use of it. A slab provides high levels of thermal mass, although heavyweight walls (on the room-side of the insulation) tend to provide better thermal mass both in winter and summer than practice physical ground slabs. Other flooring types can have thermal mass added using a number of methods, from thick ceramic tiles or slate, to adding PCMs (stage change materials).

If you alive in a bushfire zone and then fire resistance will be an important consideration. With a raised floor, you don't desire materials that can easily combust, so a heavy steel sub-floor is a practiced selection (lightweight steel subfloors can absorb heat, soften and fail). For an approach with lower embodied energy, a wooden sub-floor structure is suitable if the perimeter of the underfloor expanse is enclosed to provide fire resistance or the sub-floor is sheathed in burn down-resistant material. Either fashion, storing 'stuff' under the floor in a bushfire surface area is a bad idea.

Cost volition also exist a factor. Paying more won't necessarily provide you a amend performing issue. What generally brand flooring structures more expensive are structurally challenging compages, site gradient and requirements for thermal insulation.

The floor in any home consists of the sub-flooring system, the structural floor layer and any finished flooring material on acme. We embrace these separately below, but notation that, in many cases, the line betwixt the sub-floor and supporting floor tin can exist blurry, and in some cases in that location is no line at all—they are the same thing.

Lightweight steel framing, such equally this Spantec Systems sub-floor, is not merely termite-proof when used with steel wall and roof framing, only can reduce the number of footings required due to the ability to accept wider spans betwixt beams.

1. Sub-flooring systems

Physical slabs

Slabs are basically large solid expanses of poured physical containing reinforcing materials such equally steel mesh and reinforcing rods (commonly called rebar or reo). The slab tin be a sub-floor and floor structure, with other flooring finishes laid on superlative, or it can exist sub-floor, floor structure and floor finish if information technology is polished and finished with a articulate or coloured lacquer of some sort.

In slabs, the footings are generally integral to the slab. There are a number of different designs of slabs, depending on the site and soil requirements.

Slab on ground

In that location are many types of on-footing slabs. The simplest type consists of concrete stiffening beams poured into trenches around the perimeter of the slab, with the residue of the slab existence at least 100 mm thick. With such a slab the footings are integral to the slab.

The stiffened raft slab is a blazon of slab on footing, with additional poured concrete stiffening beams in the middle of the slab for actress force. This is a common blazon of slab in Australia, required because of soil type (only the most stable sands tin support a slab without the internal stiffening beams) or to support the house loads.

Waffle pod slabs are suitable for apartment sites and are formed by pouring concrete over polystyrene forms. This produces a slab which is adequately well insulated underneath and contains considerably less concrete and reinforcing than a stiffened raft slab. They are usually cheaper and simpler to install than other slab types, and so are popular in Australia. Waffle pod slabs can be used on soils that are moderately reactive, provided they include foundations via in-ground piers at regular spacings. All the same, with this requirement, the economy of waffle pods falls abroad.

A variation on the waffle pod slab is the Cupolex polypropylene dome arrangement, which uses an array of interlinking domes made from recycled plastic in place of polystyrene cream (see www.cupolex.com.au). Advantages include a loftier level of isolation of the slab from the ground, and the voids under the domes allow for utilities such as wiring and plumbing to be run after the slab has been poured. However, Cupolex slabs have just moderate insulation and thermal mass. The infinite under the domes can exist ventilated to eliminate moisture issues, but air menstruation under the slab will reduce thermal performance both in winter and summer.

Environmentally, the polypropylene domes may exist more easily recycled at the end of the edifice's life than the polystyrene foam in waffle pods, but both may finish upwards in landfill as separation may be considered 'also difficult'.

Pier and slab structure is used where more stability is needed due to reactive soils. Concrete piers are sunk below the slab—holes are dug at suitable intervals and filled with reinforced concrete before the slab is poured on to the tops of the piers.

Suspended slabs

Suspended slabs are another variation on the slab theme. They differ in that they use reinforced concrete panels, cast in-situ or made off-site and transported to the site, which are lifted into place with a crane.

They normally sit down on supporting walls, so are used between storeys in a multi-storey building, or can be used as the basis-flooring slab by installing short supporting walls—particularly useful for uneven blocks, as the supporting walls provide a apartment and level back up for the suspended slab.

Some suspended slabs are solid, while some have hollow sections to reduce weight and allow the running of services through the slab. The level and direction of reinforcing materials in the slab depends on where the supporting walls are located.

PROS and CONS of slabs

The primary advantages with slab structure are that slabs provide a solid, robust flooring with a high thermal mass, making them platonic where passive solar design is incorporated to collect solar proceeds during winter. However, this thermal mass can work confronting y'all in several ways, including holding heat in a abode one time a cool change has pushed through and increasing lag-time of in-floor heating systems. Concrete likewise has a high embodied energy which should exist accounted for, and information technology is also difficult to reuse at the stop of the building's life.

There are some more environmentally friendly options with lower embodied energy, collectively often known equally eco-concrete. These commonly involve concretes where a adept proportion of the Portland cement has been replaced with alternative materials, usually waste materials, such as fly ash from furnaces and ability stations. For example, Boral'due south Envisia physical has 60% less Portland cement while actually performing amend in some respects, such as reduced shrinkage and earlier strength gain. Wagner's EFC (Earth Friendly Concrete) uses a mix of wing ash and furnace slag to completely replace Portland cement. Run into the Concrete and Cement Products Guide at www.mullumcreek.com.au/concrete-and-cement for a good listing of products available, as well as give-and-take on the importance of fugitive structurally challenging compages that requires a heavy reinforced concrete floor structure with the high embodied energy that goes with that.

Some environmentally friendly concretes exercise abroad with Portland cement altogether, instead using other minerals, such as magnesium oxide. Magnesium oxide cement was developed by Novacem (which went into liquidation in 2012) and was previously available from TecEco, but this company is no longer trading. Nosotros haven't been able to find any magnesium oxide concrete products, only edifice boards (plasterboard equivalents) using this cloth. Bear in mind that the majority of all Portland clinker consumed in Commonwealth of australia is manufactured here. Magnesium oxide products are entirely imported, so they have a high ship carbon footprint.

Slab-border insulation tin be important to reduce heat loss from the slab in winter, also as heat ingress from direct sun in summer.

Stump-supported bearer and joist

The other common sub-flooring system is stump-supported. Stump-supported floors normally consist of a sub-flooring of horizontal bearers (beams used in flooring are called bearers) that support joists (a smaller, closer spaced beam on which the floor cloth rests). The bearers in plough sit down on stumps which are adjusted in length (either by beingness partially buried, cut or even adjusted, in the example of adaptable screw-jack stumps) to all exist level with each other. This makes such floors particularly useful when building on uneven or sloping ground. A structural floor layer is laid atop this supporting construction.

PROs and cons of bearer and joist sub-floors

This lightweight approach has the advantages of usually being lower price and lower embodied energy than a slab, and is easier to build on a steeply sloping or uneven block. Further, plumbing and other services can exist easily run along the joists.

The materials used tin can vary. Bearers and joists are usually wood, steel or a combination of the two. Wood bearers may be solid wood such as hardwood, simply these should be avoided as they are virtually invariably from unsustainable forestry operations from local native woods. Improve alternatives are sawn plantation pine of the required forcefulness grade or engineered timber such equally laminated-veneer lumber (e.thousand. CHH hySPAN, Wesbeam east-beam or Hyne LVL).

Steel bearers are usually standard I-beam profiles cut to length before beingness galvanised and/or painted. Some steel systems consist of rolled sheet steel which is formed to brand lightweight but strong bearers and joists. A skilful example of such a system is the Boxspan organisation from Spantec Systems, which comes complete with pre-punched screw holes, printed subclass locations and printed joist numbers next to each joist subclass, which correlate with numbers on each joist. Such a organization can reduce sub-flooring assembly time compared to a measure-and-cut system using standard-length materials.

There are too composite materials that consist of wood top and bottom flanges separated by a galvanised steel webbing to form a composite woods/steel I-axle. Notwithstanding, the timber for some of these may be imported from unsustainable sources, so check wood sources.

All bearer types have both advantages and disadvantages. Solid wood can be heavy, prone to warping, termite set on and mould/rot unless treated; although the blueprint should ensure they are not exposed to water, either from outside (such as wind-blown rain) or from leaks from wet areas. Cold rolled steel is light and strong and has a long lifespan, only has a higher embodied energy than sustainably sourced timber. Hot rolled steel is heavy and requires cranes to install; it has a very high embodied energy, although steel is most infinitely recyclable.

Stumps are unremarkably fabricated from either treated timber, bandage physical or galvanised steel. All modern stumps accept a long lifespan, and can be expected to terminal 50 to 100 years, or even longer. Some bearer and joist systems have matching stump systems from the same manufacturer, so if you choose one of those, the stump choice is made for you lot.

Prefab sub-floors/floors

With the trend towards prefabrication of some or all of a home, prefab floors have too started appearing in domestic home projects. Bearer and joist systems tin can be provided in pre-cut lengths prepare to bolt together, simplifying construction and reducing the build time on-site. Even faster installation can be had using pre-built floor sections (sometimes called cassettes), which usually consist of a steel or wood frame/joist organization with a prefixed flooring material such equally particleboard flooring screwed and/or glued into place. These tin can be particularly useful for multi-storey builds.

2. Structural flooring layer

Sitting atop the sub-floor is the structural flooring layer, often called the floor substrate. This sits under the final finished flooring material.

If y'all use a slab sub-floor, then you can skip this step as the slab is the finished supporting floor and doesn't need anything else.

For a bearer and joist sub-floor, you will demand to add a structural floor layer. This may exist tongue-and-groove particle flooring board, fibre-cement sheet, load-bearing wood or bamboo floorboards (some thin boards are meant to be supported by other materials underneath) or even more unusual materials such every bit reinforced AAC (autoclaved aerated concrete), such as Hebel PowerFloor.

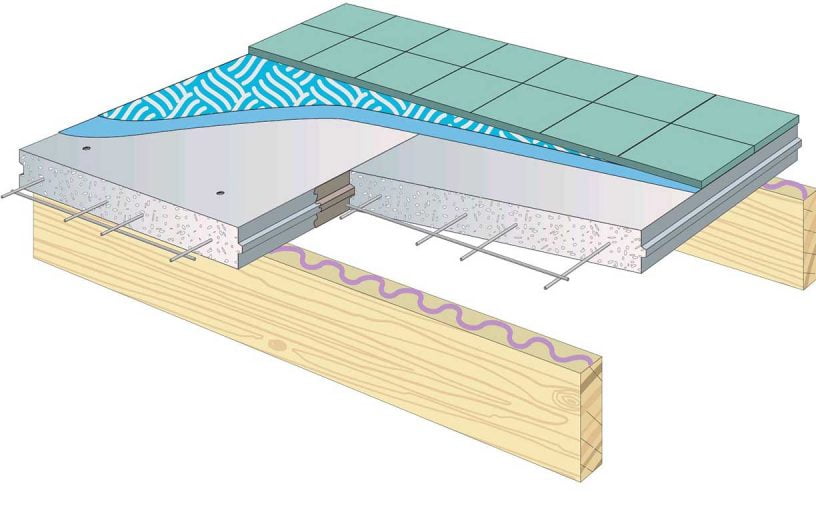

For a rigid, insulated floor, AAC panels similar Hebel PowerFloor can be used. Here you lot can encounter how the floor is assembled, with the sub-floor structure over which the PowerFloor is glued, then the waterproof membrane, adhesive layer and terminal finish layer of tiles or whatever is desired.

Wood and similar structural floor materials

Timber floorboards

When choosing a timber structural floor layer (and timber joists and bearers besides), it's of import to consider the source of the timber. Wood may be sustainably sourced, but a lot isn't. Even plantation forest (both hardwoods and softwoods are available from plantation sources) can have serious problems—after all, plantations may be located where a forest once (often quite recently) stood. However, where plantations are located on what was previously degraded/marginal open farmland (originally cleared for agriculture or mining), the ecology example in favour of plantation forestry is excellent.

When looking at wood materials for your home, you desire the best certified timber you lot can find, or to use recycled timber. The highest level of certification is FSC (Forest Stewardship Council). The Programme for the Endorsement of Forest Certification (PEFC) is likewise common, only it is less well-regarded on some compliance criteria by ecology organisations such as Greenpeace (www.scrap.ly/2GhzMCy). Cheque the Mullum Creek guide for an splendid list of more sustainable timber options for both sub-flooring and the structural flooring layers: mullumcreek.com.au/materials.

Bamboo

Bamboo has become a pop flooring selection due to its hardness and perceived eco-friendliness—you don't have to kill copse to get it, information technology is harvested yearly and simply grows back. Some bamboo is of lower quality, being harvested too early or processed the wrong mode. These bug may make it decumbent to damage from being too soft, or from warping and splitting due to moisture. Some cheaper bamboos may also have toxic glues that offgas toxic fumes such as formaldehyde.

In that location has been some business organization that bamboo is replacing hardwood forests in some areas of Asia, and so brand sure to ask for sourcing information for any bamboo products yous purchase. Besides ask about potential VOCs (volatile organic compounds) from the glues used to bond the bamboo together, besides as from the varnish used on prefinished bamboo products.

Particleboard

Like issues apply for what is arguably the virtually mutual structural floor cloth—tongue-and-groove particle floor board. This is available in diverse grades and thicknesses, just similar regular particleboard is a combination of woodchips and a resin binder, all compressed to form a dense, structurally stiff board.

Cheque for potential VOCs from your selected material and also bank check for h2o resistance, especially if your floor covering may have potential gaps where h2o may penetrate underneath during mopping, for example. These sorts of particleboards can soak upwardly water and will expand and go weak. This not but causes the floor to lift (which can exist fixed by sanding and resealing if the swelling is minimal), but may result in rotting and mould formation. If you recall this may exist a problem, the particleboard can be given two or three coats of a waterproofing sealer before the concluding floor covering is laid down.

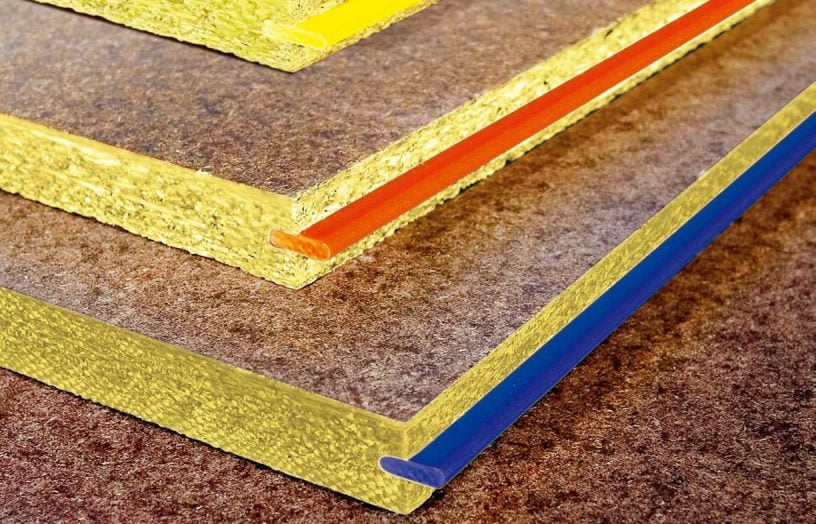

Alternatively, specify a water-resistant version, such as the wax-impregnated version of CarterHoltHarvey'southward Structaflor, which is also bachelor in a termite-resistant version, eliminating that particular problem for your floors. Structaflor is made but from plantation pine and contains no native forest materials, and there is even a thermally improved version called R-flor which has a college R-value than the standard version. However, Structaflor is not the perfect floor board every bit it only meets E1 emissions levels for formaldehyde, not E0 or Super E0.

Other structural floor materials

If your house is built on a slab, then obviously yous accept solid concrete floors only waiting to be finished, but you can become a structural cement or concrete floor layer in other ways.

Autoclaved aerated concrete

Ane interesting fabric is Hebel PowerFloor. This consists of 75 mm thick autoclaved aerated concrete (AAC) panels with an internal reinforcing construction. This allows it to be used directly on acme of joists for basis and middle floors (floors between storeys), and it can be direct covered with whatsoever flooring roofing you wish, including lino, carpet, tiles or timber.

The primary advantages with this sort of material is its inherent thermal and acoustic insulative qualities and its rigidity, which prevents move and squeaking that you get with wood-based materials. It is too very burn-resistant compared to many other materials. Ane downside is the thickness—at 75 mm it adds considerably to the thickness of the floor, and then this must be immune for in the blueprint; this makes information technology less suitable to employ every bit a retrofit over an existing floor substrate.

Fibre-cement sheeting

A thinner but still not-wood alternative is fibre-cement sheeting. This is like to cement sheeting used for wall cladding, simply is thicker and stronger and can be used as a load-begetting floor directly. 1 case is BGC Durafloor, which tin can bridge 450 mm joist spacings and is 19 mm thick. It can exist used equally a floor substrate under flooring materials such as tiles or rug, or can exist used as a floor itself, and is particularly suitable for utilise outdoors and in moisture areas. There are other manufacturers with similar products.

Tongue-and-groove particleboard is a popular floor substrate material every bit it is relatively low cost, potent and durable. The three common sizes of CarterHoltHarvey's Structaflor shown here are xix, 22 and 25 mm thick. It is as well available impregnated with wax to brand h2o-resistant and termite-resistant versions. It is fabricated from plantation pino; no native forest products are used.

3. Concluding flooring surface

The terminal floor surface that you walk on can be made of many things and, as discussed above, where the sub-flooring/structural floor layer ends and the finished floor begins tin be a blurry line. In some cases, y'all'll just exist finishing the structural floor layer; in other cases, you may be calculation a hard or soft covering.

Finishing only

Slab finishing

If you lot take used a concrete slab, then you can but coat the slab in one of many varnishes or flooring coatings available. These range from h2o-borne polyurethanes and acrylics, to epoxies, either with or without added materials to improve grip and alter the look and feel of the stop, and fifty-fifty simple oils. A elementary, depression-maintenance cease is a plain clear varnish, which shows through the natural colour of the concrete.

Concrete is easily coloured using oxides, so if you are planning a polished concrete flooring and don't want simply manifestly concrete-gray, so ask your concreter what oxide colours they can provide. Physical floors don't fifty-fifty need to be polished before blanket; you can go for the 'equally laid' expect, which should be quite shine if the concreter has done the chore well, but tin also be textured if you asking information technology.

If you decide to have polished floors, this involves grinding away the tiptop surface of the concrete to form a completely flat, smooth surface, which besides exposes some of the aggregate materials inside the concrete. This adds a more interesting look, just it tin can exist expensive and time-consuming.

Timber/bamboo/particleboard finishing

Similarly, if yous use wood or bamboo floorboards for your floor construction, the obvious step is to varnish them to provide the concluding stop. Some boards, specially bamboo boards, come up pre-finished, so you just demand to lay them into place. In older homes it is not uncommon to find beautiful hardwood floorboards covered with rug or vinyl—a error in many people'due south eyes.

For a different look yous tin can varnish tongue-and-groove particleboard sheeting. This eliminates the need for nevertheless another layer of material and gives an interesting effect of its ain, a little like cork flooring.

Whether blanket physical or timber, or another flooring roofing such as cork, make sure to consider VOCs and the sustainability of the materials used in your flooring coatings. Meet the Eco-Paint Buyers Guide in ReNew 136 for more information on VOCs.

Hard covering options

Screed on concrete

Ane option with a slab is to add a top screed layer over the concrete for the terminal desired stop. This also enables the addition of electric resistance elements or hydronic heating pipes into the screed, and so these don't demand to be in place when the slab is laid.

Floorboards

Sometimes, thin floorboards may be laid on top of a concrete slab to provide the feel and wait of woods while still taking advantage of some of the thermal mass effect of the slab. However, the two materials have different coefficients of expansion, so in this example the floorboards are all-time washed every bit a floating floor, where the boards are attached to each other just non the sub-floor structure, instead sitting on a layer of underlay. At that place'due south a simple DIY guide on laying a floating floor at www.chip.ly/2FJenqd.

Roofing particleboard with polished floorboards is besides an option. This has the advantage of the nice finish of wooden (or bamboo) floorboards while eliminating draughts between boards that are so mutual with floorboard floors that take no underlying floor substrate layer.

Ceramic, stone and slate tiles

Other options for hard flooring which can be added over all sub-floor types include ceramic tiles or slate (ideal for wet areas and kitchens) and stone tiles (thin sections of stone cut to tile-similar thickness). How much usable thermal mass these add together depends on the material and its thickness, just thin coverings are quite limited in their thermal storage capacity compared to, say, a concrete slab.

Heavy stone tiles such as marble and sandstone are very hard-wearing only can have debatable environmental credentials which can be hard to verify; these depend on the source of the stone and how far it has been shipped—a lot of stone originates on the other side of the globe, so it has very loftier transport miles associated with information technology.

There are other interesting products such as Regal Oak Floors Concreate slab tiles (see www.royaloakfloors.com.au/concreate), which consist of a natural language-and-groove wood panel finished with a thin layer of concrete which is prefinished, oiled and polished. The panels are suitable for gluing onto new floors or retrofitting over any stable sub-flooring, including existing wooden floors. Note that while such systems will give you the look of concrete, they won't have the thermal mass effect of a solid concrete floor.

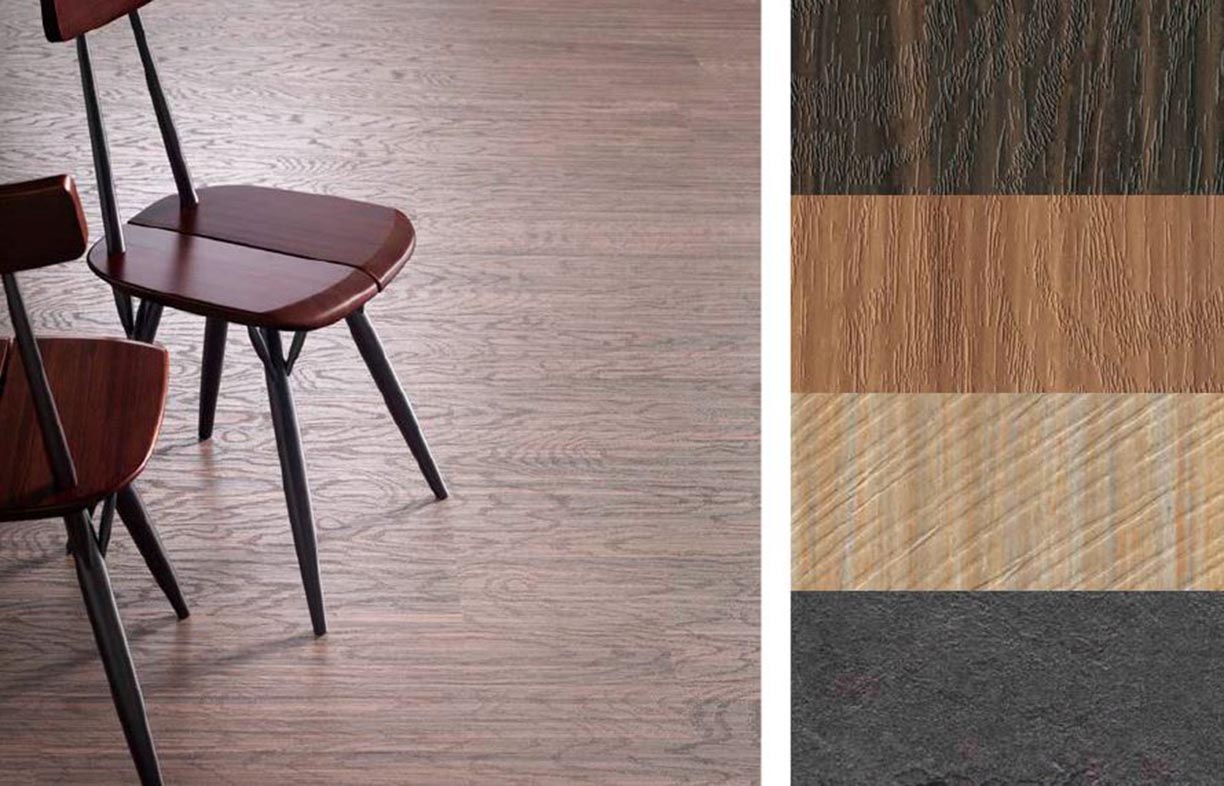

Linoleum is bachelor in a huge range of colours, patterns and textures, such equally the woodgrain and slate texture finishes shown here, from the Marmoleum range from Forbo Flooring Systems. Lino is also available in rolls or tiles of various sizes, so almost any desired issue can be achieved. Even ameliorate is that lino is made completely from natural materials such as linseed oil, wood flour, tree resin, limestone and natural pigments, so no toxic off-gassing occurs as it does with constructed materials such as vinyl.

Laminates

Other hard flooring options include various laminates, often made from compressed fibre boards with vinyl or other coatings; many of these are of unknown quality, immovability and environmental sustainability, and may off-gas considerably in the starting time year or two. Some laminates are much better than others, so exercise your homework if you lot get downwards this path.

Soft covering options

Of course, at that place are also softer floor coverings that can be used on any structural floor layer.

Carpets and carpet squares

The obvious option is carpet, which comes in different materials such as synthetic fibres (nylon, polypropylene or polyester, all of which are difficult-wearing and stain-resistant, but an environmental problem at cease of life) and wool (a natural fibre but you need to consider its ethical credentials; it can also stain easily). One advantage of wool carpets is burn resistance—wool won't support a fire on its own, whereas synthetics and other fibres may. Wool can also exist composted at end of life, provided it is a pure wool blend with no synthetic fibres in the tufts or backing. A variation on carpet is rug squares or tiles, such as the Heuga Interface drove (world wide web.interface.com). Carpet tiles let tiles to be replaced or rotated for more than even habiliment and a longer lifespan.

And don't forget carpet underlay. Some carpets take underlay congenital in, so check what it'due south made of to avoid buying a natural carpet with a synthetic underlay. For flooring coverings that don't have an integrated underlay, try to select a natural material if bachelor, such as Airstep natural rubber.

Coir, jute etc

Woven coir, sisal, jute and seagrass are too available and are natural materials that volition only compost at the finish of life. However, they can be harder to keep make clean than synthetics and will generally have a shorter lifespan in loftier traffic areas.

Cork

Another option that is similar to but softer than a 'hard' flooring material is cork. Cork is the bawl of the cork tree, which is removed from the tree without killing information technology, causing information technology to grow back over fourth dimension. A lot of cork tiles and flooring are at present made from recycled cork, then your floor may already exist on its second apply when you lot buy it. Once installed (installation depends on the type of cork flooring you buy), information technology should be sealed with a polyurethane sealant to protect information technology from stains and scuff marks. Article of furniture legs volition damage cork flooring and should sit in felt-bottom furniture cups.

Vinyl and Linoleum

Also in the semi-soft flooring category are of course vinyl (we don't recommend this due to the high level of off-gassing of plasticisers) and the natural equivalent, linoleum, which is made from mineral powders, linseed oil, cork or wood dust and pine resin every bit a binder. Colour pigments are also usually natural materials and linoleum is almost completely biodegradeable.

Rubber

Rubber flooring, while non as common as the others mentioned above, tin be very durable and give a prissy finish, while feeling warmer underfoot than hard tiles. It's by and large a natural textile made from latex and is biodegradeable, provided it is fabricated from natural rubber not a synthetic. In that location are several brands, including a composite cork and rubber material chosen Comcork (world wide web.comcork.com.au) which is around lxx% cork and is available in polish or textured surfaces for college grip levels, and Regupol Everroll (world wide web.regupol.com.au/everroll), made from pre- and post-consumer waste matter safety.

In-floor heating

One part of many newer floors is integrated heating. This can exist in the form of a hydronic organization, using an array of pipes, or it can use resistive elements, unremarkably in the form of resistive wire or sheet film.

Hydronics are ordinarily laid in slab floors, either in the slab itself, or added to the height of the slab in a suitably thick screed layer (an actress layer of concrete added later on the slab is complete). The pipes are laid into the concluding positions, usually divided upward into zones so that only detail areas need to be heated if desired, and the concrete poured effectually them. Obviously, the pipes must remain leak-gratuitous for the life of the slab, and so only pipework and fittings designed for in-slab hydronics should be used and it should be installed by someone trained in that particular system. Fixing leaking pipes in a finished slab can be expensive and messy!

Resistive underfloor heating tin can be added nether any floor surface or covering due to the simplicity of the textile. It consists of either thin wires or thin sheets of heating elements laid under tiles, carpet or whatever flooring end yous determine upon. Resistive heating systems are cheaper than hydronics to install, but a big disadvantage is that they tin can use a lot of energy, and and so can exist very expensive to run.

In-floor heating when washed with a slab has ane major disadvantage—at that place is considerable thermal lag as the slab takes time to heat upwards. So, if your climate is prone to rapid changes in temperature, and especially if it has long shoulder seasons for heating (then you find yourself regularly wanting to turn space heating on and off), heating the slab may non be your best option. You may be amend off having the heating system thermally isolated from the thermal mass of the slab (for example, using heating film on elevation of rigid insulation, topped by your chosen floor roofing; but bear in mind that resistive heating systems can utilize a lot of electricity and are usually expensive to run), or using a different heating organization birthday, such as reverse-bike air-conditioning or far-infrared panels.

Concrete tiles are available for both walls and floors and provide a polished concrete finish without the need for a concrete slab. They can be retrofitted to any stable floor.

If you exercise decide to install in-slab heating, yous must make certain that the slab is fully insulated, underneath and around the edges, otherwise you are paying to heat the basis under and around the slab!

Draughtproofing

Some types of floor, such as floorboards, tend to accept problems with draughts if they are non well installed. As mentioned earlier, a floor volition exist far less draughty if floorboards are laid over another material such equally particleboard flooring. If boards are laid directly onto the sub-floor structure then they should be sealed between the boards or sealed underneath using an appropriate sealant. A spray-on insulation, such every bit SprayIT Solutions, is economically viable for new and existing suspended timber floors and will both insulate and seal in i get. It is also of import to seal around the edges of the flooring, regardless of the type of floor, to prevent draughts getting in between the edges of the floor and the walls, under the skirting boards. This should be done as the house is being built, but like the problem of wall and ceiling insulation being incorrectly installed by builders, sealing flooring-to-wall gaps is often not done correctly, or at all.

Thermal operation

In many areas, especially cooler climate zones, considerable thermal functioning comeback to the edifice envelope can be had with a good degree of thermal insulation of the flooring.

For bearer and joist floors this can accept the form of rigid batts fitted between joists, foil and composite foil/bulk insulation materials stapled or fitted betwixt joists or nether joists (in the example of canvass materials) or fifty-fifty spray-on foam materials. Regardless of the material used, it needs to meet several of import criteria, including flammability resistance and vermin resistance, and information technology must exist installed in a way that information technology won't motion over time. For this reason, soft batts (like wall and ceiling batts) that are held in place nether a flooring with strapping or mesh are non recommended. At that place are similar materials with embedded reinforcement designed specifically for flooring uses, such as Earthwool Underfloor, which has an integrated wind wash bulwark (to prevent air current damage to the batts).

A more involved system involves creating an insulated flooring crenel. For example, y'all might lay a 12 mm thick structural plywood substrate over the floor joists, fit 70 to 90 mm deep pine battens over this at standard centres, and insulate the floor cavity betwixt these battens with Earthwool or polyester batts. Floorboards are then laid over this. The result is a well-insulated flooring with no draughts, a handy services cavity and no vermin access.

For slabs, whether you accept insulation nether the slab or not depends on your location. A slab that isn't insulated will effectively mirror the temperature of the ground at a depth of around three metres. In climates with huge diurnal fluctuations that for much of the year oscillate near equally to either side of the desired internal temperature, this lets yous use the relatively stable temperatures of the soil to stabilise the temperature inside the house.

In colder regions (areas with colder winters), it is advantageous to insulate the slab equally the ground temperature is simply too cold in winter for comfy living. This is particularly the case for passive solar homes which are designed to store heat from nerveless sunlight in the slab. In cold regions, uninsulated slabs simply leak estrus into the soil, losing nigh of the collected warmth. Once again, whether the slab is insulated or not depends on several factors, including your climate, but also the rest of the house design. This is something that needs to be discussed with your architect.

Waffle pod and similar slab systems provide insulation under the slab, but if your program is to eliminate the use of plastic foams or similar products, so you can all the same insulate nether the slab using natural materials. Ane such insulative material is ClinkaFILL, an aerated clay aggregate that can be used under and even inside a slab to improve thermal performance.

While insulating under the slab decouples the slab from the basis temperature, an frequently-overlooked area is the edge of the slab, where considerable heat can be lost (or gained in summer). The edge of the slab should be insulated using appropriate insulating materials—there are products specifically designed for this task. For more data on slab edge insulation, see 'Avoiding unseen heat loss' in ReNew 138. The Mullum Creek project has also produced a slab insulation guide: world wide web.mullumcreek.com.au/app/uploads/Ground-Slab-Insulation-Guide.pdf.

Thermal mass can be an important part of a passive solar dwelling house. In a well-designed dwelling, thermal mass tin shop estrus from sunlight during winter, keeping the home warmer in the evening for longer and providing a college average temperature through colder months.

We have mentioned concrete as a source of thermal mass, simply other high mass materials that tin be used in this mode include rock, bricks and heavy tiles. As previously mentioned, heavyweight walls (on the room-side of the insulation) can provide adept thermal mass, so consider this as an alternative when using a lightweight flooring.

For homes with lightweight floors, you can use phase change materials, which shop warmth as latent heat in materials that undergo a stage change (from solid to liquid—i.east. they melt) at a temperature that is comfortable for the house occupants, usually in the range of 18 to 28 °C. These materials may be organic, such every bit based on waxes or solid oils, or mineral based. The material is encapsulated in plastic membranes, forming a sheet of small cells of the PCM fabric, assuasive them to be used in walls, ceilings and floors.

A hydronic organization is often an integral part of a slab floor. Hither a organisation is being added to the existing slab. The pipes are laid and a screed of physical is poured over them.

Phase modify materials tin can exist used immediately under many floor types, including floorboards, fibre-cement sheet and like supportive materials, but at that place must be a loftier level of insulation nether the PCMs and a high caste of thermal coupling between the PCMs and the flooring surface. This coupling can be difficult to achieve, depending on the caste of contact between the layers, and the thickness, density and hence conductivity of the floor material.

Summary tables

Summary tables of both sub-floor systems and flooring materials are available here.

About the author

Lance Turner is Renew magazine's technical editor.

- Engineered Forest Products Clan of Australasia: www.ewp.asn.au

- Your Dwelling—concrete floors: www.yourhome.gov.au/materials/concrete-slab-floors

- Australian Timber Flooring Association Floor Choices website: world wide web.floorchoices.com.au

- Mullum Creek Materials Guides: www.mullumcreek.com.au/materials

When deciding on the material types for the various parts of your build, you should consider the following for your sub-floor structure:

- Does information technology suit your block's blazon of soil and location?

- Does it suit the balance of build? e.grand. heavy materials require a solid sub-floor.

- Does it accept the required termite and rot resistance for your location?

- Is information technology suitable for the area in general? east.k. coastal or tropical regions.

- Is it within the build upkeep?

- Practice you need high thermal mass?

- If edifice a slab floor, should it be coupled to the soil or not?

- What level of underfloor insulation is required for your location?

- Does it run into the sustainability and recyclability criteria for the project?

Before deciding on the nigh advisable flooring, you should consider the following:

- What level of durability and maintenance is required?

- How critical to y'all is the use of natural materials and sustainability, recyclability and biodegradability?

- What level of stain resistance and ease of cleaning is required? due east.g. textured difficult floors, especially textured vinyls, can trap clay and require actress effort to make clean.

- Is information technology suitable for the specific area in the house? e.g. moisture areas and kitchens, where spills are frequent, require materials that are waterproof and easy to clean.

- Should the materials feel warm or cool underfoot?

- Should the flooring experience soft or hard underfoot?

- Are the materials suitable for in-flooring heating, if required?

- Does the material have the desired level of reflectivity? e.k. reflective tiles may produce glare if sunlight hits them directly.

- How fire-resistant is the material?

- Consider longevity of the manner.

This article was first published in Issue 143 (Apr-Jun 2018) of Renew magazine. Upshot 143 is our edifice materials special, including a window buyers guide and an article on flooring options.

Related articles

Buyers guides

Buyers guides

A cladding buyers guide

23 Dec 2019

Building cladding is non but for aesthetics; it is an integral part of a building's envelope and needs to be carefully selected to ensure the best performance. Lance Turner looks at cladding options and the pros and cons of each material blazon.

Read more than

Source: https://renew.org.au/renew-magazine/building-materials/the-right-floor-for-your-build/

Posted by: mcclainwhatlet.blogspot.com

0 Response to "Should Plywood Be Rolled Or Spray Painted"

Post a Comment